Table of Contents

- Bolt Anatomy: Understanding the Parts

- Essential Measurement Tools

- Measuring Bolt Diameter Correctly

- Determining Thread Pitch

- Measuring Bolt Length

- Identifying Head Types & Drive Styles

- Standard vs. Metric Identification

- Understanding Grade & Strength Markings

Bolt Anatomy: Understanding the Parts

Before measuring, it's crucial to understand bolt terminology. As a hardware specialist who's helped thousands of DIYers identify fasteners, I've found that confusion about these basic terms causes most identification errors:

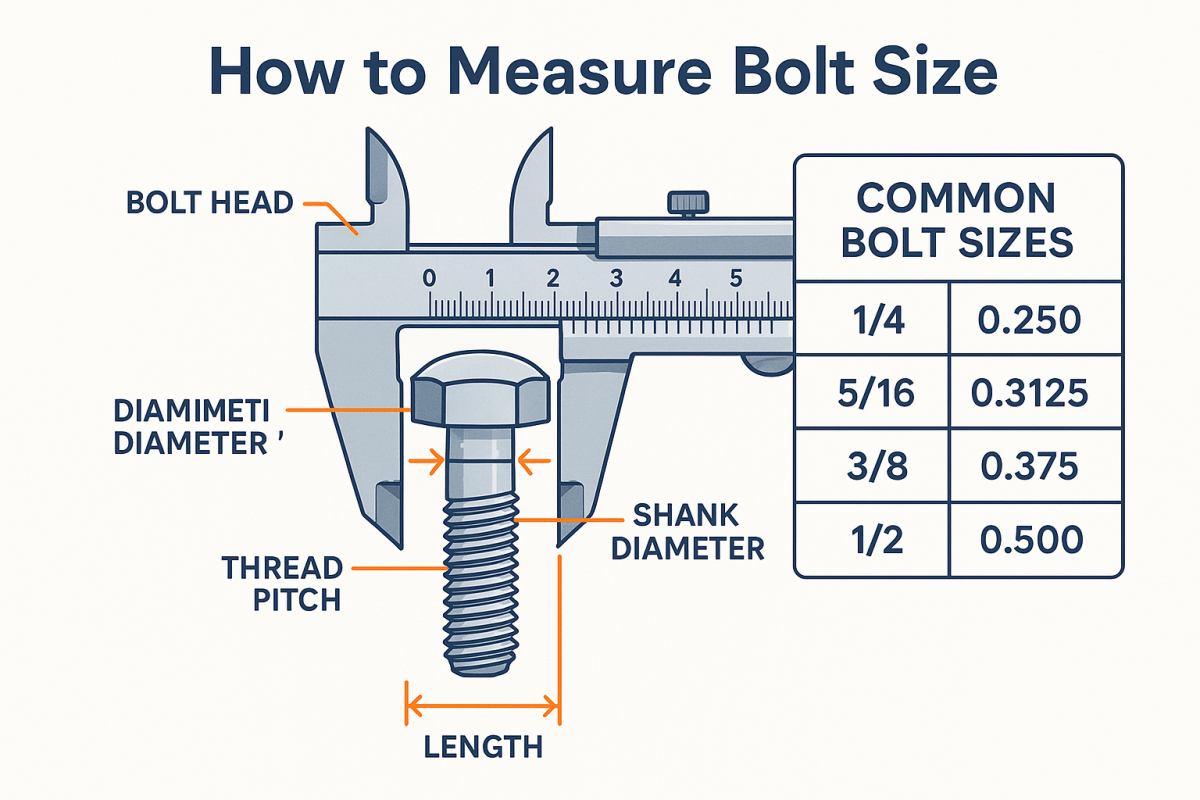

Major Diameter

The largest diameter of the bolt's threads, measured from crest to crest

Thread Pitch

The distance between adjacent thread crests (metric) or threads per inch (standard)

Shank Length

The measurement from under the head to the tip of the bolt

Head Dimensions

The size and shape of the bolt head, including drive type

Last month, a customer brought me a box of mixed bolts from an inherited workshop. By teaching them these basic concepts, we identified 87 different bolt sizes in under an hour using our bolt size finder kit.

Essential Measurement Tools for Bolt Identification

Having the right tools makes bolt identification accurate and straightforward:

| Tool | Best For | Accuracy | Skill Level |

|---|---|---|---|

| Caliper | Precise diameter and length measurements | ±0.001" | Intermediate |

| Thread Gauge | Determining thread pitch | Exact match | Beginner |

| Bolt Gauge | Quick size identification | ±1 size | Beginner |

| Ruler/Scale | Approximate measurements | ±1/16" | Beginner |

| Thread Checker | Definitive thread identification | 100% accurate | All levels |

Measuring Bolt Diameter Correctly

Diameter measurement seems simple, but it has nuances that often trip people up:

For Standard (Imperial) Bolts:

- Measure the major diameter (outer thread peaks)

- Convert to fractional inches (¼", ⅜", ½", etc.)

- Refer to standard size charts for exact designation

For Metric Bolts:

- Measure the major diameter in millimeters

- This measurement refers to the bolt size (e.g., M6, M8, M10, etc.).

- Note that M6 measures approximately 6mm, M8 measures 8mm, etc.

When a customer insisted they had "5/16-inch" bolts that wouldn't fit 5/16-inch nuts, we discovered they were measuring the shank instead of the threads. The actual diameter was M8 (approximately 5/16" is actually 7.94mm, close to 8mm). Our thread checker quickly resolved the confusion.

Determining Thread Pitch: The Detailed Approach

Thread pitch identification separates beginners from pros:

Standard (Imperial) Threads

Measure how many thread peaks fit in 1 inch

Example: 13 peaks in 1" = 13 threads per inch (TPI)

Metric Threads

Measure the distance between adjacent thread peaks in millimeters

Example: 1.5mm between threads = 1.5mm pitch

Using a Thread Gauge

Match gauge teeth to bolt threads until you find a perfect fit

The gauge label indicates the pitch

Fine vs. Coarse Threads

Coarse threads have larger spacing between threads

Fine threads have closer spacing for precision applications

For standard bolts, the size is written as diameter-TPI (¼"-20). For metric bolts, it's diameter-pitch (M8-1.25). This distinction is crucial for proper identification.

Measuring Bolt Length: Where Most People Go Wrong

Bolt length measurement seems straightforward, but it has specific rules:

| Bolt Type | Measurement Method | Examples |

|---|---|---|

| Standard Hex Bolts | Under head to tip | ½" x 2" (diameter x length) |

| Socket Head Caps | Top of head to tip | M6 x 30mm |

| Shoulder Bolts | Under the head to the end of the shoulder | ¼" x 1" x ½" (diameter x shoulder length x thread length) |

| Countersunk Bolts | Overall length (head included) | #10 x 1½" |

I recently helped a carpenter who was frustrated that his "2-inch" bolts were too short. He was measuring from the top of the head instead of from the bearing surface. This ¼" difference caused his project fittings to be misaligned.

Identifying Head Types & Drive Styles

While head style doesn't affect thread size, it's crucial for replacement and tool selection:

Hex Head

Six-sided head, requires a wrench

Most common for structural applications

Socket Head

Cylindrical with internal drive

Requires Allen/hex keys

Pan Head

Rounded top with vertical sides

Often used with a Phillips drive

Flat Head

Conical shape for countersinking

Measured, including head height

Drive styles include Phillips, slotted, Torx, square (Robertson), and hex. While these don't affect the bolt size, they determine what tools you'll need for installation and removal.

Standard vs. Metric Identification: Key Differences

Mixing standard and metric systems causes most bolt identification errors:

| Characteristic | Standard (Imperial) | Metric |

|---|---|---|

| Measurement System | Inches (fractions) | Millimeters (decimals) |

| Thread Designation | Threads per inch (TPI) | Pitch in millimeters |

| Common Sizes | ¼", ⅜", ½", ⅝", ¾" | M6, M8, M10, M12, M14 |

| Head Markings | Radial lines for grade | Numbers for the grade |

| Wrench Sizes | Fractional (⅜", ½", etc.) | Metric (10mm, 13mm, etc.) |

Understanding Grade & Strength Markings

Bolt head markings indicate material strength and proper applications:

Standard Bolt Grades:

- Grade 2: No markings, low strength

- Grade 5: 3 radial lines, medium strength

- Grade 8: 6 radial lines, high strength

- ASTM A325: Structural bolts

Metric Bolt Classes:

- Class 4.6: No numbering, low strength

- Class 8.8: Most common, medium strength

- Class 10.9: High strength

- Class 12.9: Highest strength

Never substitute a lower-grade bolt for a higher-grade application, especially in structural or automotive contexts. The consequences can be dangerous.

Using a Thread Checker Tool: The Professional Approach

A dedicated bolt size finder simplifies identification:

- Clean the Bolt: Remove dirt and debris from threads

- Start with Standard or Metric: Choose based on the origin of the equipment

- Test Multiple Sizes: Try different thread gauges until a perfect match

- Check Fit: The Proper gauge should screw on smoothly without play

- Verify Diameter: Use calipers to confirm the diameter measurement

Our nut and bolt thread checker features both standard and metric sizes, with clear markings that eliminate the guesswork in identification. I've trained dozens of DIYers who can now identify any bolt in seconds using this tool.

Common Measurement Mistakes to Avoid

After years of helping customers identify bolts, I've seen these recurring errors:

Measuring Shank Instead of Threads

Shank diameter is often smaller than the thread diameter

Always measure the threaded portion

Ignoring Thread Pitch

Assuming the diameter alone determines compatibility

Pitch must match for proper engagement

Confusing Standard & Metric

Assuming close measurements are interchangeable

5/16" ≠ M8 (7.94mm vs 8mm)

Incorrect Length Measurement

Measuring from the wrong reference point

Results in bolts that are too long or too short

These mistakes lead to stripped threads, damaged components, and safety hazards. Using a dedicated bolt size finder prevents these issues entirely.

Selecting Replacement Bolts: Beyond Basic Measurements

When replacing bolts, consider these additional factors:

- Material Compatibility: Match or upgrade material (stainless, zinc-plated, etc.)

- Grade Requirements: Never downgrade strength ratings

- Head Style: Ensure proper clearance and tool access

- Thread Length: Match engagement requirements

- Environmental Factors: Consider corrosion resistance needs

Frequently Asked Questions

How can I tell if a bolt is standard or metric?

Measure the diameter: if it aligns with common fractional inches (¼", ⅜", ½"), it's likely standard. If it aligns with whole millimeters (6mm, 8mm, 10mm), it's metric. A bolt size finder provides definitive identification.

What if my bolt measurements don't match standard sizes?

You may have a specialized thread (fine thread, UNF, etc.) or a worn bolt. Try both standard and metric thread checkers, and consider that the bolt might be damaged or non-standard.

Can I use a metric bolt in place of a standard one?

Generally not. Even similar sizes (like ½" and M13) have different thread pitches and strength ratings. Always replace with the same type and grade.

How do I measure bolts with damaged threads?

Measure the shank diameter and length, then use a thread checker on a nut that fits the bolt. For severely damaged bolts, alternative identification methods may be needed.

Why do some bolts have multiple thread pitches?

Many bolt sizes come in coarse and fine thread variants. Fine threads offer better vibration resistance, while coarse threads install faster and are less likely to cross-thread.

Mastering Bolt Identification: Your Key to DIY Success

Accurately identifying bolt sizes transforms frustrating guesswork into confident repairs. As we've explored, successful bolt identification requires:

- Understanding bolt anatomy and terminology

- Using proper measurement techniques and tools

- Recognizing the differences between the standard and metric systems

- Interpreting grade markings for safety

- Avoiding common measurement mistakes

For DIYers and professionals alike, our nut and bolt thread checker is the ultimate solution for accurate, frustration-free bolt identification. With both standard and metric sizes in one durable tool, you'll never struggle with bolt sizes again. Stop guessing and start knowing with confidence!