If you've ever repaired a car panel, built sheet-metal furniture, or worked with thin-gauge materials, you've probably encountered rivets and rivet nuts. Knowing when to use a rivet nut gun versus a traditional rivet gun will save you time and get stronger, more serviceable results. This long-form guide explains the mechanics, pros & cons, real-world applications, and step-by-step instructions — all written in plain English for busy makers and pros.

Quick Answer — In One Line

Rivet gun = installs blind rivets (permanent). Rivet nut gun = installs threaded rivet nuts (creates bolt-ready threads in thin materials).

What Is a Rivet Gun? (Basics and Variants)

A rivet gun (commonly called a "pop rivet gun" in DIY circles) is built to set blind rivets. Blind rivets consist of a hollow body and a mandrel. The mandrel is pulled through the rivet body, causing the back end of the rivet to flare and clamp the joined materials together. The mandrel snaps off when the rivet is fully set — leaving a permanent join.

Types of rivet guns

- Hand (manual) rivet gun: Affordable and portable; good for occasional use and small projects.

- Lever rivet gun: For more leverage and faster work; common in body shops and fabrication shops.

- Pneumatic rivet gun: Air-driven; used for high-volume or heavier-duty rivets.

- Hydraulic rivet gun: High force, industrial applications.

Common rivet materials and head styles

Rivet bodies come in aluminum, steel, stainless steel, and sometimes copper or brass. Head styles include dome (standard), countersunk, and large-flange for soft materials.

What Is a Rivet Nut Gun? (Basics and Why It Exists)

A rivet nut gun installs rivet nuts — metal inserts that become captive, loadable females in thin material. Think of a rivet nut as a lightweight, one-sided anchor: once installed, it provides a proper threaded hole for a bolt or machine screw where a tapped thread cannot be made.

Varieties of rivet nut guns

- Manual rivet nut tools: Hand-held, economical; great for occasional installs and lighter rivet nuts.

- Threaded mandrel kits: Interchangeable mandrels for multiple nut sizes (M4, M5, M6, 1/4-20, etc.).

- Pneumatic rivet nut guns: Faster, less physical effort; common in production environments.

- Hydraulic / battery rivet nut guns: Used when larger collars or high volumes demand more force.

Why use a rivet nut instead of a rivet?

Because rivet nuts allow you to remove and replace the screw multiple times. They transform thin metal panels, aluminium extrusions, or composite panels into serviceable assemblies with bolt access. That makes them ideal for machine enclosures, automotive panels, brackets, and retrofit assemblies.

How They Work — Mechanics & Simple Diagrams

Rivet gun mechanics (pop rivet)

1) Insert rivet into hole. 2) Pull mandrel using the rivet gun. 3) Mandrel draws, deforming rivet tail into a mushroom shape. 4) Mandrel snaps when sufficient deformation is reached. Result: permanent clamp.

Rivet nut gun mechanics

1) Insert rivet nut into a pre-drilled hole. 2) The rivet nut gun pulls the threaded mandrel into the nut body, collapsing the blind end inward to form a bulge behind the client material. 3) This bulge creates a firm bearing against the backside of the panel; the nut remains captive and threaded for bolts.

Side-by-side Comparison — Rivet Gun vs. Rivet Nut Gun

| Characteristic | Rivet Gun (Blind Rivets) | Rivet Nut Gun (Nutserts / Rivet Nuts) |

|---|---|---|

| Primary function | Creates permanent joints by deforming rivet body. | Creates a threaded insert for bolts & screws. |

| Reusability | No — rivets are permanent. | Yes — bolts/screws can be removed & reinstalled repeatedly. |

| Typical use materials | Sheet metal, aluminium, thin steel, plastics (where permanent join required). | Thin metal, composite panels, aluminium extrusions, plastic panels where threads are needed. |

| Strength (shear & tensile) | Good shear for light-medium loads; permanent joint offers consistent shear performance. | High axial/tensile capacity for bolted connections; depends on nut size and material. |

| Ease of install | Very simple; many hand tools available. | Simple for moderate sizes; some larger sizes need heavy duty tools or pneumatics. |

| Cost | Low cost per fastener; rivet guns are inexpensive. | Higher per-threaded fastener cost; tools more specialized. |

| Removal / servicing | Removal can be destructive (drill out rivet). | Bolts can be removed; rivet nut may remain functionally intact for multiple uses. |

Reference Tables — Sizes, Hole Diameters, & Suggested Tools

Common rivet nut sizes & recommended hole diameters

| Rivet Nut Size | Thread | Hole Diameter (mm) | Hole Diameter (in) | Typical Use |

|---|---|---|---|---|

| Rivet Nut M4 | M4 x 0.7 | 6.0 mm | 0.236" | Light brackets, small enclosures |

| Rivet Nut M5 | M5 x 0.8 | 7.4 mm | 0.291" | Medium brackets, panel connections |

| Rivet Nut M6 | M6 x 1.0 | 8.4 mm | 0.331" | Heavier panels, mounting hardware |

| Rivet Nut 1/4-20 | 1/4-20 UNC | 7.8 mm – 8.0 mm | ~0.31" | Standard US bolt sizes for brackets |

Typical shear & tensile guidance (approximate)

Values depend heavily on material, thread engagement depth, and nut material. These are ballpark numbers for mild steel panels and steel rivet nuts.

| Thread Size | Approx. Shear Strength (kgf) | Approx. Tensile Strength (kgf) |

|---|---|---|

| M4 | ~500–800 kgf | ~600–1000 kgf |

| M5 | ~800–1200 kgf | ~900–1400 kgf |

| M6 | ~1200–2000 kgf | ~1400–2600 kgf |

Always check manufacturer datasheets for precise load ratings for the specific rivet nuts and materials you use.

Applications & Real-World Use Cases

Automotive: Why mechanics choose rivet nuts

Automotive panels are often thin-gauge steel or aluminum where tapping threads is impractical. When mounting accessories, brackets, or retrofitting parts, a rivet nut gun creates secure threaded points without compromising panel integrity. For example, mounting a roll cage clamp, attaching trim, or installing sensors often uses rivet nuts.

Aerospace & Aviation

Blind rivets are ubiquitous in aircraft skins due to weight, reliability, and historical precedent. Rivet guns (pneumatic or specialized bucking tools) are used extensively. Rivet nuts are less common for exterior skins, but used in interior panels and assemblies where threaded attachments are necessary.

Furniture & Enclosures

Flat-pack furniture, electronics enclosures and display panels benefit from rivet nuts: manufacturers can create threaded anchor points without thick metal. That allows easy serviceability and replacement.

DIY & Makers

For the home workshop, a rivet nut gun is a frequent purchase once you want bolts rather than screws — for example, building a light steel frame with detachable panels or attaching accessories to bike frames.

How to Choose the Right Tool — Practical Decision Tree

Answer these three quick questions:

- Do you need a threaded connection (bolt/screw) later? — If yes → use a rivet nut gun.

- Will the joint be permanent and not serviced? — If yes → a rivet gun with a suitable rivet body is fine.

- Is the panel very thin or a composite where tapping threads will damage material? — If yes → rivet nuts are strongly recommended.

Budget & Frequency considerations

- Hobbyist / occasional use: Manual rivet nut tools or a small hand rivet gun are economical.

- Semi-professional: Multi-mandrel rivet nut tools (interchangeable heads) and a lever rivet gun save time.

- Production: Pneumatic or battery rivet nut guns and pneumatic rivet guns increase throughput.

Installation Guides — Step-by-step (with pro tips)

How to install a blind rivet (rivet gun)

- Pick the correct rivet size for material thickness.

- Drill or punch the right-sized hole; deburr edges.

- Insert rivet through materials; seat the rivet head flush on the outside.

- Use the rivet gun to pull the mandrel until it snaps — the backside will mushroom and clamp the materials.

- Check the fit, trim any protruding mandrel stub if necessary (usually not needed).

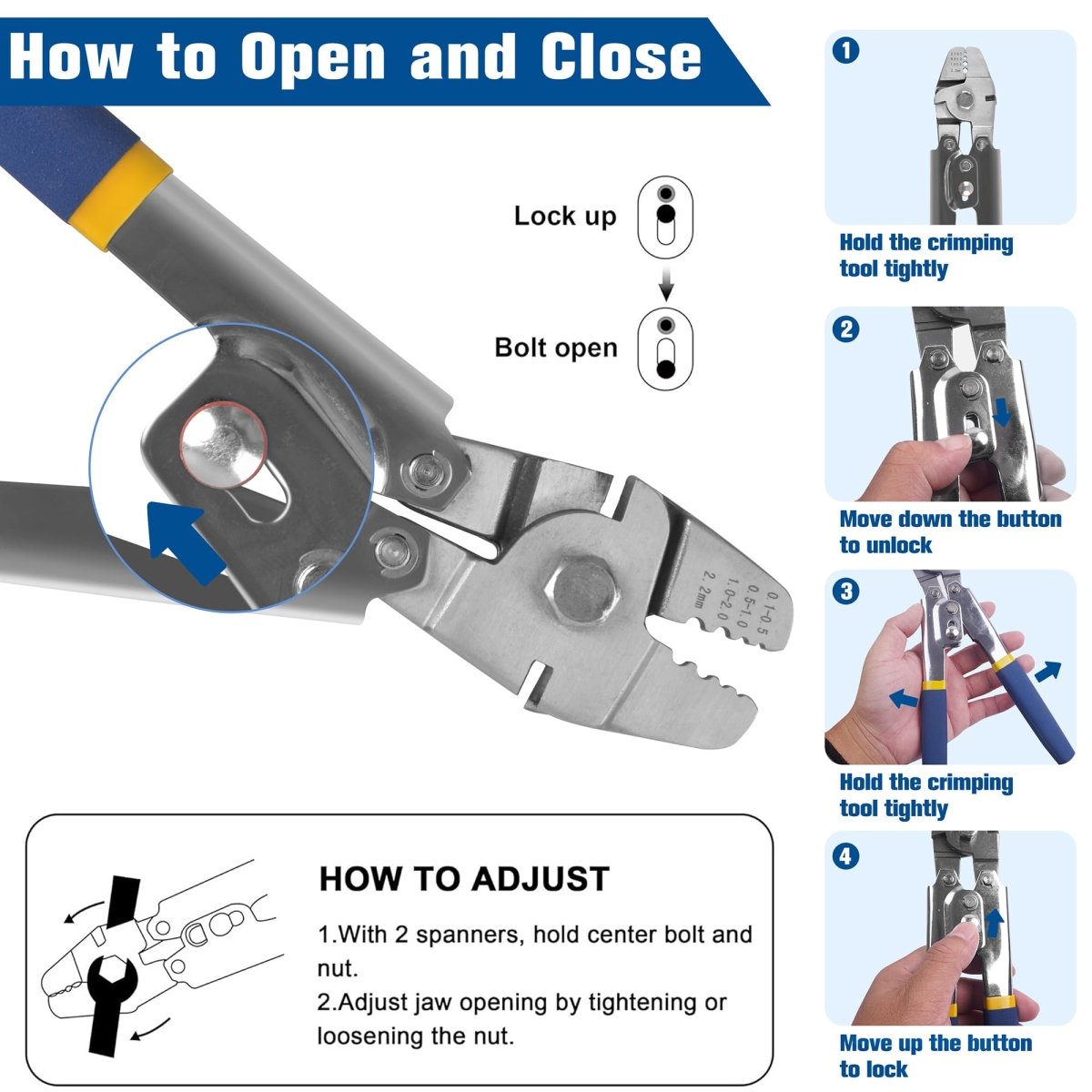

How to install a rivet nut (manual rivet nut gun)

- Select the correct rivet nut size and matching mandrel for the tool.

- Drill the precise hole diameter recommended for the rivet nut (see tables above).

- Screw the rivet nut onto the mandrel of the tool.

- Insert the rivet nut into the hole, square to the panel.

- Operate the tool (squeeze handles / trigger) to compress the nut body and form the bulge behind the panel.

- Unscrew the mandrel, leaving the rivet nut captive and ready for a bolt.

Pro tips for cleaner installs

- Clamp workpieces to prevent movement and misalignment during setting.

- Always use a backing board when drilling thin panels to avoid blowout.

- For soft plastics, use rivet nuts with larger flange or use a bonded washer to increase load distribution.

- Mark and pilot-drill holes in jigs for repetitive installs to maintain consistent alignment.

Tools, Mandrels, & Accessories You’ll Want

- Interchangeable mandrel sets: Make a rivet nut tool useful across multiple thread sizes.

- Backing plates & washers: For soft materials or to increase bearing area.

- Thread-lockers: Use removable thread locker (blue) for assemblies that may loosen under vibration.

- Punch & die sets: For cleaner holes and countersinking where needed.

- Torque-limited drivers: For bolting into rivet nuts without over-torquing threads.

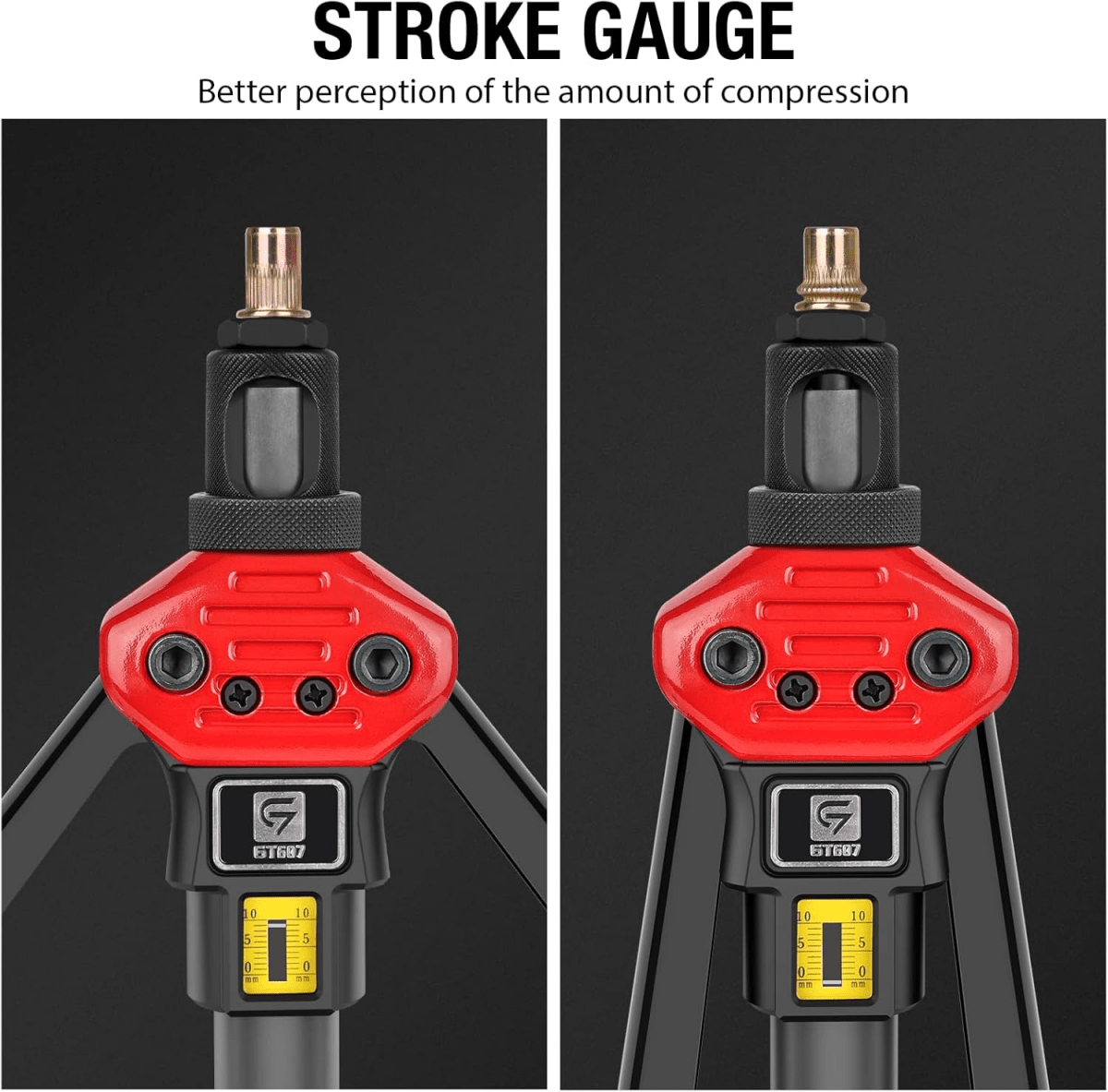

If you're just starting, a kit like this one gives you mandrels, multiple staples of rivet nuts, and the hand tool to test: 16 Rivet Nut Gun Kit.

Maintenance, Safety, and Best Practices

Tool maintenance

- Wipe down tools after use and apply light oil to moving parts for long life.

- Replace worn mandrels and nosepieces — they wear out and can damage rivet nuts.

- Check alignment regularly; a misaligned mandrel can cross-thread or deform a rivet nut.

Safety

- Wear eye protection — rivet mandrels often snap and can eject small fragments.

- Clamp or secure small parts to avoid pinch hazards during installation.

- For pneumatic tools, ensure air hoses are in good condition and pressure settings are correct.

Case Studies — When Choosing the Right Fastener Made a Difference

Case Study A — Aftermarket Winch Mount (Automotive)

Problem: Thin bumper brackets needed secure mounts for a winch. Traditional welding altered the bumper and created heat issues. Solution: Install M6 rivet nuts along the internal channel to provide torque-rated bolt points. Outcome: Bolts hold to rated torque, serviceable, and the bumper remains intact for future modifications.

Case Study B — Trade Show Kiosk

Problem: A trade-show display used lightweight aluminum panels with removable sections. Tapping threads wasn't possible without thick supports. Solution: Use M5 rivet nuts to create captive threaded points for quick panel removal. Outcome: Tool-less assembly at events, reduced labor, and increased reusability over multiple shows.

Case Study C — Emergency Repair Truck

Problem: A field repair required a quick replacement of a bracket with only one side accessible. Solution: Blind rivets on non-structural parts and rivet nuts for places that would need a bolt for future removal. Outcome: Faster repairs and easier replacement during follow-up maintenance.

Troubleshooting: Common Problems & Fixes

Problem: Rivet nut spins when tightening bolt

Causes & fixes:

- Hole too large — replace with larger-diameter nut or install a washer behind for larger bearing area.

- Thin or brittle substrate — use rivet nuts designed for thin sheets or use nutserts with larger flange.

- Improper collapse — ensure proper mandrel and tool settings; re-install with correct mandrel size.

Problem: Mandrel breaks prematurely

- Check that the mandrel matches the rivet nut size and is not worn or damaged.

- Avoid excessive leverage on manual tools — use a heavier tool or pneumatic option for larger nuts.

Problem: Uneven collapse or deformed flange

Ensure the nut is square and the hole is clean and deburred. A countersink might be needed for soft or layered materials.

❓ Frequently Asked Questions

- Q1: Can I use a rivet gun to install rivet nuts?

- A1: No. Standard rivet guns pull mandrels and are not designed to form threaded nut inserts. You need a rivet nut gun or a threaded mandrel tool to form rivet nuts.

- Q2: Are rivet nuts as strong as tapped threads?

- A2: Rivet nuts can provide very strong and repeatable threads in thin materials. They are often stronger than poorly tapped thin materials and are preferred where full-depth tapping isn’t feasible.

- Q3: Do rivet nuts require blind-side access?

- A3: No — rivet nuts are designed for one-sided installation, similar to blind rivets. That’s their main advantage for many panels and assemblies.

- Q4: What sizes should I stock for general workshops?

- A4: M4, M5, M6 and 1/4-20 are common useful sizes. If you do vehicle work, include M6 and 1/4-20. Having multiple flange styles and materials (steel, stainless, large flange) is useful.

- Q5: Can rivet nuts be used in plastics?

- A5: Yes — but choose rivet nuts with larger flange or use backing plates to prevent pull-through. There are also specialized insert styles for plastic use.

Glossary & Quick Reference

- Blind rivet:

- A rivet set from one side only; the mandrel is pulled to form a blind-side head.

- Rivet nut / Rivet nut gun:

- A threaded insert that is deformed to clamp to the blind side of a panel, installed with a rivet nut gun.

- Mandrel:

- The rod used by a tool to draw or collapse a fastener during installation.

- Flange:

- The outer head of a rivet nut or rivet which bears on the outside surface; larger flanges help distribute load.

Further Reading & Resources

- Manufacturer datasheets for specific rivet nut load ratings

- Safety and tool manuals for pneumatic rivet guns

- Community tutorials and videos showing practical installs

Conclusion — Which One Should You Use?

Use a traditional rivet gun when you want a permanent, tamper-resistant joint and you do not need a threaded connection later. Use a rivet nut gun when you need a serviceable, threaded point in thin materials where traditional tapping is impossible or would weaken the panel.

For most workshops and repair shops that value flexibility — especially in automotive, furniture, and enclosure work — a reliable rivet nut gun is a highly practical investment. If you'd like a starter kit that includes common sizes and mandrels to prototype with, check this kit: 16 Rivet Nut Gun Kit.